High Purity okisijeni jenareta okisijeni jenareta vagadziri

Kushanda Nheyo

Mamorekuru eNitrogen ane kukurumidza kupararira mwero mumikropores yezeolite molecular sieve, uye mamorekuru eokisijeni ane mwero unononoka wekupararira.Kupararira kwemvura uye carbon dioxide mumhepo yakamanikidzwa kwakafanana neiyo nitrogen.Pakupedzisira, mamorekuru eokisijeni anofumiswa kubva kune adsorption tower.Pressure swing adsorption oxygen kugadzirwa inoshandisa yakasarudzika adsorption maitiro ezeolite molecular sieve, inotora kutenderera kwekudzvanywa adsorption uye decompression desorption, uye inoita kuti mweya wakamanikidzwa upinde mushongwe yeadsorption neimwe nzira kuti uone kupatsanurwa kweokisijeni nenitrogen, kuti irambe ichiburitsa yakakwira. -kuchena uye okisijeni yepamusoro.

PSA okisijeni jenareta inotora yemhando yepamusoro zeolite se adsorbent zvinoenderana nemusimboti wekumanikidza swing adsorption.Pasi peimwe dzvinyiriro, okisijeni inobviswa mumhepo, yakacheneswa uye yakaomeswa mhepo yakamanikidzwa, uye yakamanikidzwa adsorption uye decompression desorption inoitwa mune adsorber.Nekuda kweiyo aerodynamic mhedzisiro, chiyero chekupararira kwenitrogen mumikropores yezeolite molecular sieve yakakwira zvakanyanya kupfuura iyo yeokisijeni.Nitrogen inonyanya kushambadzirwa ne zeolite molecular sieve, uye okisijeni inowedzerwa muchikamu chegasi kuita okisijeni yapera.Zvino, mushure mekudzvinyirirwa kumhepo yemhepo, molecular sieve inobvisa iyo adsorbed nitrogen uye humwe hutsvina kuti uone kuvandudzwa.Kazhinji, maviri adsorption shongwe akaiswa muhurongwa, imwe yeadsorption uye kugadzirwa kweokisijeni, uye imwe yekubvisa uye kuvandudzwa.Iyo PLC program controller inodzora kuvhurwa nekuvhara kwevhavhavha yepneumatic kuita kuti shongwe mbiri dzitenderere zvakachinjana, kuitira kuti iwane chinangwa chekuenderera mberi kwekugadzirwa kweiyo okisijeni yemhando yepamusoro.

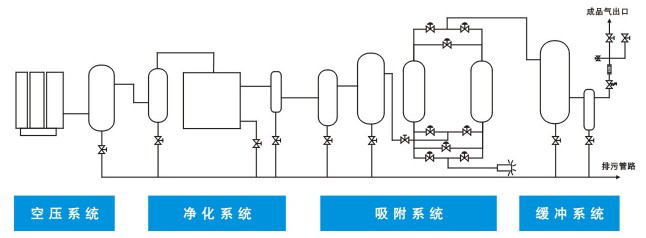

Kuyerera kwehurongwa

Iyo yakakwana yekugadzirwa kweokisijeni system ine zvinotevera zvikamu:

Air compressor ➜ buffer tank ➜ compressed air purification device ➜ air process tank ➜ oxygen nitrogen separation device ➜ oxygen process tank.

1. Air compressor

Semhepo sosi nemidziyo yemagetsi yejenareta yenitrogen, mhepo compressor inowanzosarudzwa sescrew muchina uye centrifuge kuti ipe mweya wakatsikirirwa wakakwana kune jenareta renitrogen kuti ive nechokwadi chekushanda kwakajairika kwejenareta renitrogen.

2. Bhafa tangi

Mabasa etangi rekuchengetedza ndeaya: kuvharidzira, kudzikamisa kudzvanywa uye kutonhora;Kuti uderedze kuchinjika kwehudzvanyiriri hwehurongwa, bvisa zvizere kusvibiswa kwemvura-mafuta kuburikidza nevhavha yepasi, ita kuti mweya wakamanikidzwa upfuure nemuchikamu chekuchenesa mweya wakamanikidzwa, uye uve nechokwadi chekushanda kwakavimbika uye kwakagadzikana kwemidziyo.

3. Yakatsikirirwa mhepo yekuchenesa mudziyo

Iwo mweya wakamanikidzwa kubva mubhafa tangi unotanga kuunzwa mumudziyo wakamanikidzwa wekuchenesa mweya.Mazhinji emafuta, mvura uye guruva zvinobviswa ne-high-efficiency degreaser, uye zvino zvinowedzera kunyoroveswa nechando chakaoma chekubvisa mvura, kubvisa mafuta uye kubviswa kweguruva nesefa yakanaka, iyo inoteverwa nekucheneswa kwakadzika.Zvinoenderana nemamiriro ekushanda kwehurongwa, hande kambani yakanyatso gadzira seti yakamanikidzwa yemhepo degreaser kudzivirira inogona kuteedzera kupinza mafuta uye nekupa dziviriro yakakwana kune molecular sieve.Iyo yakanyatsogadzirwa yekuchenesa mhepo module inovimbisa hupenyu hwesevhisi yezeolite molecular sieve.Mhepo yakachena inobatwa neiyi module inogona kushandiswa kune gasi rekushandisa.

4. Air process tank

Basa rekuchengetedza mhepo tangi kudzikisa kuyerera kwemhepo pulsation uye buffer;Kuti uderedze hurongwa hwekumanikidza kushanduka uye kuita kuti mhepo yakamanikidzwa ipfuure nepayakamanikidzwa mhepo yekunatsa musangano, kuitira kuti ibvise zvizere mafuta-mvura tsvina uye kuderedza mutoro unotevera wePSA okisijeni uye nitrogen yekuparadzanisa unit.Panguva imwecheteyo, panguva yekuchinja kwebasa re adsorption tower, inopawo PSA oxygen uye nitrogen separation unit ine huwandu hukuru hwemhepo yakamanikidzwa inodiwa kuti ikurumidze kusimuka munguva pfupi, izvo zvinoita kuti kumanikidzwa mu adsorption tower kukwira kusvika. iyo yekushanda kudzvinyirira nekukurumidza, kuve nechokwadi chekuvimbika uye kugadzikana kushanda kwemidziyo.

5. Oxygen nitrogen separation unit

Kune maviri adsorption shongwe a uye B akashongedzerwa yakakosha molecular sieve yeokisijeni jenareta.Kana mweya wakachena wakadzvanywa uchipinda mujinga meshongwe uye uchiyerera uchienda kumagumo kuburikidza nesefa yemamorekuru, nitrogen inoshambadzwa nayo, uye okisijeni yechigadzirwa inoyerera ichibva kumagumo ekubuda kweadsorption tower.Mushure menguva yakati, iyo molecular sieve mushongwe a yakazara.Panguva ino, shongwe inomira otomatiki adsorption, mhepo yakamanikidzwa inoyerera ichipinda muShongwe B yekutora nitrogen uye kugadzirwa kweokisijeni, uye inogadzirisazve sefa yemamorekuru yeshongwe a.Kudzokororwa kwemolecular sieve kunowanikwa nekukurumidza kudzikisa adsorption tower kumhepo yemhepo uye kubvisa iyo adsorbed nitrogen.Idzi shongwe mbiri dzinoita adsorption uye kugadzirwa patsva kupedzisa okisijeni nenitrogen kupatsanurwa uye nekuenderera mberi nekuburitsa okisijeni.Aya maitiro ari pamusoro anodzorwa ne programmable logic controller (PLC).Kana iyo kuchena kweokisijeni panzvimbo yekuburitsa gasi yaiswa, chirongwa chePLC chinovhura otomatiki vent valve kuti iburitse okisijeni isina kukwana, kucheka iyo okisijeni isina kukodzera kubva pakuyerera ichienda kunzvimbo yekushandisa gasi, uye shandisa silencer kuderedza ruzha pasi pe78dba. panguva yekufambisa gasi.

6. Oxygen process tank

Iyo oxygen buffer tank inoshandiswa kuenzanisa kudzvanywa uye kuchena kweokisijeni yakaparadzaniswa neiyo nitrogen okisijeni yekuparadzanisa system kuti ive nechokwadi chekuenderera uye kwakadzikama kupihwa kweokisijeni.Panguva imwecheteyo, mushure mekushandurwa kwebasa kweiyo adsorption tower, inochajazve chikamu chegasi rayo mushongwe yeadsorption, iyo isingangobatsiri kukwira kweiyo adsorption tower, asi inoitawo basa mukudzivirira mubhedha, uye inotamba. basa rinokosha zvikuru rekubatsira mubasa rekushanda kwemidziyo.

Technical Parameters

Okisijeni kubuda: 5-300nm3 / h

Okisijeni kuchena: 90% - 93%

Oxygen pressure: 0.3MPa

Dew point: -40 ℃ (pasi pesimba rakajairwa)

Unyanzvi Zvimiro

1. Mhepo yakamanikidzwa yakashongedzerwa nemhepo yekuchenesa uye yekuomesa kurapa mudziyo.Mhepo yakachena uye yakaoma yakamanikidzwa inokodzera kurebesa hupenyu hwesevhisi ye molecular sieve.

2. Iyo itsva pneumatic stop valve ine kukurumidza kuvhura uye kuvhara kukurumidza, hapana kuvuza uye hupenyu hurefu hwebasa.Iyo inogona kusangana nekuvhurwa kazhinji uye kuvhara kwekumanikidza swing adsorption process uye ine yakakwirira kuvimbika.

3. Yakakwana dhizaini dhizaini kuyerera, yunifomu kugovera kwemhepo, uye kuderedza kukurumidza-kumhanya kwemhepo kuyerera.Zvikamu zvemukati zvine simba rekushandisa uye mutengo wekudyara

4. Iyo molecular sieve ine simba rakawanda, kushanda kwepamusoro uye kushandiswa kwesimba shoma kunosarudzwa kuti ive nehungwaru kudzora iyo isina kukodzera oksijeni venting system kuti ive nechokwadi chehutano hweokisijeni.

5. Midziyo yacho ine kuita kwakagadzikana, kushanda kuri nyore, kushanda kwakadzikama, dhigirii yakakwira yeotomatiki, mashandiro asina kurongwa uye kuderera kwegore kutadza kushanda.

6. Inotora PLC kutonga, iyo inogona kuona yakazara-otomatiki kushanda.Inogona kuve yakashongedzerwa neokisijeni mudziyo, kuyerera, kuchena otomatiki regulation system uye kuremote control system.

Munda Wekushandisa

1. EAF steelmaking: decarbonization, oxygen combustion heat, foam slag kunyunguduka, metallurgical control uye post heat.

2. Kugadziriswa kwemvura yetsvina: okisijeni yakafumisa aeration yeakagadziriswa sludge, pool oxygenation uye ozone sterilization.

3. Kunyunguduka kwegirazi: kupisa kweokisijeni uye kupera, kucheka, kuwedzera girazi rinobuda uye kuwedzera hupenyu hwevira.

4. Pulp bleaching uye papermaking: chlorine bleaching inoshandurwa kuita oxygen yakakwenenzverwa bleaching kuti ipe oxygen netsvina yakachipa.

5. Non ferrous metal smelting: okisijeni hupfumi hunodiwa pakunyungudutsa simbi, zingi, nickel uye lead, uye nzira yePSA zvishoma nezvishoma inotsiva cryogenic nzira.

6. Okisijeni yeindasitiri yepetrochemical uye indasitiri yemakemikari: hupfumi hweokisijeni hunoshandiswa kutsiva mweya weiyo oxidation reaction mune okisijeni reaction muindasitiri yepetrochemical uye indasitiri yemakemikari, inogona kuvandudza kukurumidza kwekuita uye kubuda kwemakemikari zvigadzirwa.

7. Ore processing: inoshandiswa mugoridhe uye mamwe maitiro ekugadzira kuvandudza chiyero chekuchera chesimbi dzinokosha.

8. Aquaculture: okisijeni inopfumisa aeration inogona kuwedzera okisijeni yakanyungudika mumvura, kuwedzera zvakanyanya kugadzirwa kwehove, kutakura okisijeni yehove mhenyu uye kusimudza hove zvakanyanya.

9. Kuvirisa: kupfumisa okisijeni kunotsiva mweya kuti upe okisijeni yekuvirisa aerobic, iyo inogona kuvandudza zvakanyanya kushanda kwemvura yekunwa.

10. Ozone: ipa okisijeni kujenareta yeozone kuti uzvigadzirise okisijeni.

11. Chipatara: ipai mubhedha kufema oxygen.Kuchena, kuyerera uye kudzvinyirira kwakadzikama uye kunogadziriswa kuzadzisa zvinodiwa nevatengi vakasiyana.